Messer/Mayer Mill Improvements

Almost Lost--

What

is that old rundown building tucked back in the woods off Pleasant Hill

Road in Richfield, Wisconsin? Raccoons probably have a heyday in there.

It sure looks like a fire hazard. However, the Town of Richfield and a

group of Town residents didn't feel that way about the Messer/Mayer

Mill. The Town purchased the Mill and Homestead property in 1998. The

Town Chairman, Ralph Schulteis, said, "It would be shame to let this

go." A local newspaper stated "By buying Mayer's Mill, Richfield

preserves a piece of Town's past."

What

is that old rundown building tucked back in the woods off Pleasant Hill

Road in Richfield, Wisconsin? Raccoons probably have a heyday in there.

It sure looks like a fire hazard. However, the Town of Richfield and a

group of Town residents didn't feel that way about the Messer/Mayer

Mill. The Town purchased the Mill and Homestead property in 1998. The

Town Chairman, Ralph Schulteis, said, "It would be shame to let this

go." A local newspaper stated "By buying Mayer's Mill, Richfield

preserves a piece of Town's past."

Preservation Begins--

Once the property was purchased, the newly formed Richfield Historical

Society (RHS) took over the restoration and maintenance of all the

buildings on the Messer/Mayer Homestead. The historic buildings are all

there—just like they were when the last mill operator, George Mayer,

left the property in 1971.

What

has been done to the Mill by the Society with its "Can Do" attitude

since the property was purchased? The list is pretty lengthy. The first

order of business was to get rid of the branches that had grown right

through the roof. Handel’s Tree Service donated their services to

tackle that problem. Once that was completed, Foresters Roofing donated

and placed a huge blue tarp over the roof to cover the holes left by

the branches that had been removed.

What

has been done to the Mill by the Society with its "Can Do" attitude

since the property was purchased? The list is pretty lengthy. The first

order of business was to get rid of the branches that had grown right

through the roof. Handel’s Tree Service donated their services to

tackle that problem. Once that was completed, Foresters Roofing donated

and placed a huge blue tarp over the roof to cover the holes left by

the branches that had been removed.

Volunteers at Work--

The mill and the other buildings on the

property were cleaned out—taking away all the debris that had

accumulated over the years. Dan Wittenberger  and

a crew of RHS volunteers removed the old rotted material and replaced

it with cedar shingles which matched the character of the mill. If you

would visit the 3rd floor of the Mill today, you would not recognize

that the roof had been replaced.

and

a crew of RHS volunteers removed the old rotted material and replaced

it with cedar shingles which matched the character of the mill. If you

would visit the 3rd floor of the Mill today, you would not recognize

that the roof had been replaced.

Every piece of the siding on the Mill had to be replaced. Before it

could be replaced, it had to be painted. So, the Society organized

'painting parties.' The long pieces of siding were placed on a

customized rack and the coat of primer plus two coats of Mill red paint

meticulously covered each piece. Wonder if the volunteer painters still

have any of those clothes that probably had more red paint on them than

was on the siding. Those 'painting parties' were a lot of fun and

helped bond the Society members. As the siding was painted,

Every piece of the siding on the Mill had to be replaced. Before it

could be replaced, it had to be painted. So, the Society organized

'painting parties.' The long pieces of siding were placed on a

customized rack and the coat of primer plus two coats of Mill red paint

meticulously covered each piece. Wonder if the volunteer painters still

have any of those clothes that probably had more red paint on them than

was on the siding. Those 'painting parties' were a lot of fun and

helped bond the Society members. As the siding was painted, completed boards were installed on the Mill. This project took two years –2002 through 2004

completed boards were installed on the Mill. This project took two years –2002 through 2004

Because either the windows were broken or the frames were rotted, all 25 of the windows had to be rebuilt and the glass replaced. This was a painstaking job and required the skills of woodworkers. Fortunately, the Society had such talented volunteers who took on this task. Most of the glass was replaced with the old-fashioned type that has 'swirls' when you look through it—giving the mill an authentic look.

With the roof, windows, and siding all in place, the animals lost their happy home. The rain, sleet, and snow would no longer play havoc with the valuable original equipment inside the Mill--the millstones, sifting machines, hoppers, grain elevators, roller mills, and much more.

Inside Repairs--

Work then turned to the inside of the Mill. In 2002, Bender Builders

from Beaver Dam, jacked up and straightened the interior of the Mill.

Because the roof had leaked for so many years, much of the flooring had

rotted. In 2003 and 2004, basswood boards were cut from the trees that

were taken down from the overgrown property. This lumber was used to

repair the 2nd and 3rd floors. Two stands of the roller mills (a newer

method of grinding grain) were refurbished. Additional repairs have

been made to the beams, joists, and flooring on the 3rd level. One of

the sifting machines has been reworked. A set of gravity elevators now

moves grain from floor to floor.

Many tours go through the Mill during the Events of the Society. There was always a bottleneck in getting visitors from the 2nd floor down to the 1st floor with only one set of stairs. This situation was remedied by putting in another flight of stairs so visitors can go up to the 2nd floor via one set of stairs but return to the 1st floor via the new set—much more efficient. The stairs were built to look as if they had always been there.

Power Sources--

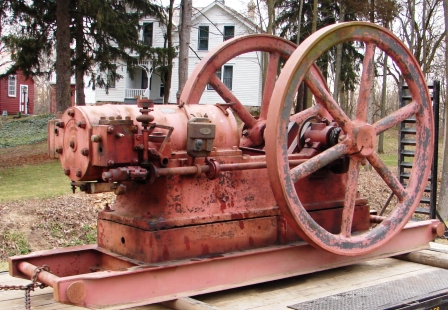

Let’s

move back to the outside for further improvements. The water

chase which will eventually carry water into the Mill to power the

turbine was rebuilt as an Eagle Scout project. However, until approval and funds can be  obtained

to reconstruct the dam for a mill pond, the Mill will need a different

power source. This will be a 1913 Superior gas engine very similar to

the one that once ran the Mill during some of its lifetime. This was

purchased in 2006. The front steps were moved to the west side and

steps were built on the east side to replicate the original look of the

front of the Mill.

obtained

to reconstruct the dam for a mill pond, the Mill will need a different

power source. This will be a 1913 Superior gas engine very similar to

the one that once ran the Mill during some of its lifetime. This was

purchased in 2006. The front steps were moved to the west side and

steps were built on the east side to replicate the original look of the

front of the Mill.

Restoring the Foundation--

As time took its toll on the limestone mortar and stone foundation,

large cracks were found and stones were falling out of place. After

over 150 years, this wasn't unexpected. Much consideration was given to

this situation, and in 2009 the foundation was stabilized by Marion

Restoration  until

the funds could be raised to restore the foundation to pristine

condition. Because the entire building will shake when the millstones

will eventually turn, the foundation must be firm.

until

the funds could be raised to restore the foundation to pristine

condition. Because the entire building will shake when the millstones

will eventually turn, the foundation must be firm.

Finally, sufficient funds were raised to restore part of the foundation (Phase 1). In 2013, the northern basement wall and portions of the east and west walls were tuckpointed and repaired. One part of the west basement wall had to be rebuilt entirely. The remainder of the east and west walls as well as the very tall south wall still needs to be rebuilt. Fundraising efforts continue at this time to finance that very expensive project.

During Phase 1 of the foundation restoration, the basement stairs had been dismantled. This stairway has been rebuilt in a much sturdier fashion. Also, a door opening was added to the basement so tours can now see that portion of this Mill.

During Phase 2 of the restoration, a path leading to the basement was made, a door was hand built for the opening, a retaining wall was put in place with an attractive safety railing across the top.

Phase 3: the foundation of the Messer/Mayer Mill has been completely restored and should last another 150 years. Also, the Leffel turbine was dug from its muddy grave and will be restored to its glory by a volunteer. A Big Thank You to everyone who donated funds over the past 7 years to make this foundation restoration possible.

Phase 3: the foundation of the Messer/Mayer Mill has been completely restored and should last another 150 years. Also, the Leffel turbine was dug from its muddy grave and will be restored to its glory by a volunteer. A Big Thank You to everyone who donated funds over the past 7 years to make this foundation restoration possible.

What's Next--

The next step is to rebuild the engine shed which will house the gasoline engine. This engine will provide the power to turn the millstones until water can once again flow down the raceway. All of the shafting needs to be connected so the large millstones can once again make

wheat into flour. Other machinery inside the Mill will need refurbishing. The task to "Get the Mill Grinding" is far from over. Click here to find out how you can help continue with this restoration.

be connected so the large millstones can once again make

wheat into flour. Other machinery inside the Mill will need refurbishing. The task to "Get the Mill Grinding" is far from over. Click here to find out how you can help continue with this restoration.